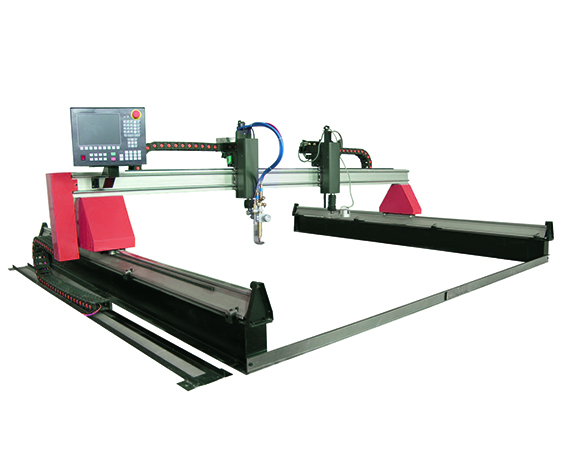

CNC CUT Gentry X1

CNC CUT Gentry X1

The system has two torch holders, one for plasma cutting and one for flame cutting. It is quick to install and can also be extended at the customer’s request – a powerful upgrade for portal plasma cutters! Replace the aluminum beam with more stable and stronger steel. A new patented triangular aluminum guide rail has been added. The guide rail is attached to the square steel and ensures the tracking accuracy and strength of the beam. Increase the cutting stability and thus improve the cutting quality.

A mixture of capacitive and arc voltage-dependent height control. A water-cooled device which is used in the thin sheet metal range below 1 mm.

Features

– A simple, menu-driven interface is easy to learn and use.

– Integrated library with common shapes

– Data transfer storage is convenient and flexible: supports USB port for loading programmes.

– G-code dynamic simulation processing function

– Notch compensation

– Complex curve fitting function Supports import and export of files in various formats

– A simple, menu-driven interface is easy to learn and use.

– Integrated library with common shapes

– Data transfer storage is convenient and flexible: supports USB port for loading programmes.

– G-code dynamic simulation processing function

– Notch compensation

– Complex curve fitting function Supports import and export of files in various formats

Optional:

– Software:Libellula® Wizard 3 nesting software for the PC

Optional:

– upgrate X-axis and Y-axis expandable per metre

Model | CNC CUT Gentry X1 |

|---|---|

Supply Voltage | 230 V, AC/110V AC, 50/60 Hz |

Drive | 750W x 2, 400W x 1, AC Panasonic Servosystem, Dual drive |

Cutting mode | Oxyfuel and plasma |

Cutting Speed | Oxyfuel: 0- 1.000mm/min, Plasma: 0 – 10.000mm/min |

Movement speed | 0 – 10.000 mm /min. |

Effective cutting range | 2.000 x 4.000 mm |

Height control | THC |

Cutting tolerance | ≤ 0,5 mm |

Positioning accuracy | ± 0.3mm |

Repeat positioning accuracy | ± 0.3mm |

Cutting thickness | Plasma: Due to the power source |

Weight | 650 kg |

Measurement (LxWxH) | 3800x1220x1250 |

Item number | 02.02.55.04020 |

Data sheet