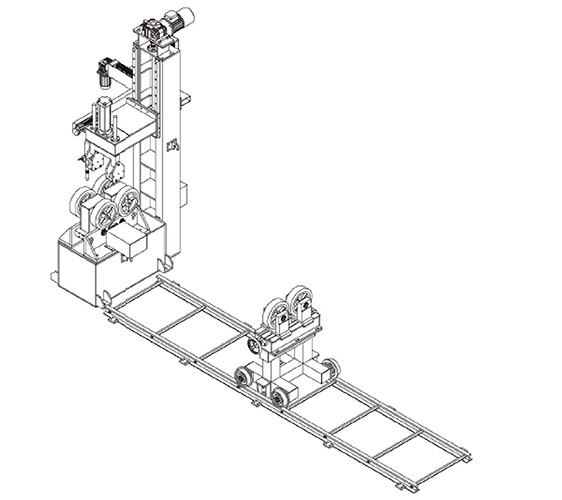

Pipe Processing Unit RW Rotator

RW Rotator

Up and down movement

The RW Rotator is used for turning and welding round

round profiles using manual or automatic welding processes, mainly in the field of pipeline construction, prefabrication and on-site assembly.

Features

– The RW welding rotator is used for rotating and welding round profiles using manual or automatic welding processes, mainly in the field of pipeline construction, prefabrication and on-site assembly.

– Due to the rotation of the pipe, no interruption is observed when welding the pipe in the circumferential direction.

– The RW welding template as standard, up and down movement for diameter adjustment is carried out mechanically by handwheel. On request, Optional, A quick assembly-disassembly equipment can be provided.

– Compact and sturdy design

– For welding, cutting and grinding

– Clamping without chuck A wide range of pipes can be processed Even pipe elbows or flanges are no problem Pipe bends and pipes with flanges can also be accommodated.

– Clamps precisely and quickly without jaw chuck.

– Overlap welding possible

Scope of delivery:

1 tracking unit 2 pieces

1 cable remote control

Optional:

further followers possible

Wireless hand-held remote control

Wireless pendant control

Double foot switch

Control panel

Model | RW-1 | RW-6 |

|---|---|---|

Max. Load | 2000 kg | 6000 kg |

Workpiece diameter | 100 – 400 mm/min | 100 – 620 mm/min |

Min. Min. workpiece length | over 450 mm | over 600 mm |

Roller speed | 240 – 2400 mm/min | 240 – 2400 mm/min |

Roller diameter | 200 mm / Wide: 50 mm | 250 mm / Wide: 60 mm |

Motor drive | DC400W180V | DC1HP/180V |

Model | PLC control with HMI display (RW1T) | PLC control with HMI display (RW6T) |

|---|---|---|

Power | AC380V / 50Hz /3-Phasen | AC380V / 50Hz /3-Phasen |

Welding start | 2-cycle, 4-cycle | 2-cycle, 4-cycle |

Memory | 1 – 99 | 1 – 99 |

Overlap | 0.0 – 25,0 mm | 0.0 – 25,0 mm |

Crater Arc Timer | 0.0 – 10.0 Sec | 0.0 – 10.0 Sec |

Roller rotation speed | 240 – 2400 mm/min. | 240 – 2400 mm/min. |

Arc voltage | 60 -250VDC | 10 -45VDC |

Data sheet