Control Systems + Gear Boxes

Turntable gearbox series for PRO turntables and COM series control units

1) Choose a gearbox for your PRO turntable

With the different gears you have the possibility to adjust the speed of your PRO-turntable to your requirements. You can determine before buying *, with which gear or which speed your turntable should be equipped.

You can also find a large selection of gearboxes with different speeds here

Model | Rotating speed | Gear Boxes |

|---|---|---|

Positioner Pro 2 PN | 2,4 to 24 u/min 1,2 to 12 u/min 0,6 to 6 u/min 0,4 to 4 u/min 0,2 to 2 u/min | 5GN15B 5GN30B 5GN6ßB 5GN90B 5GN180KB |

Positioner Pro 3 PN | 2,4 to 24 u/min 1,2 to 12 u/min 0,6 to 6 u/min 0,4 to 4 u/min 0,2 to 2 u/min | 5GX15B 5GX30KB 5GX60KB 5GX90KB 5GN180KB |

Positioner Pro 4 PN | 1,2 to 12 u/min 0,6 to 6 u/min 0,4 to 4 u/min 0,2 to 2 u/min 0,1 to 1 u/min | 5GN3B 5GN6B 5GN90B 5GN15B 5GN30B |

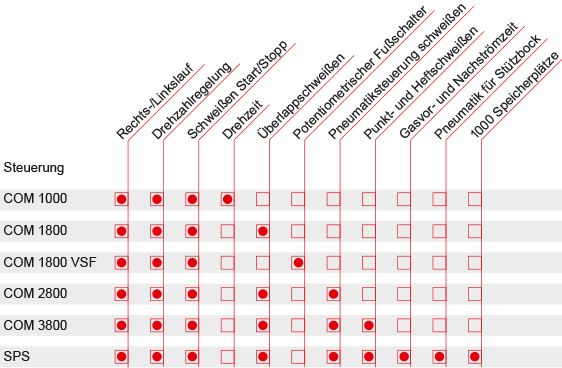

2) Choose a control unit for your PRO turntable

Pay only for functions that you really need. Before you purchase, determine which control unit best meets your requirements.

Model | Rotating speed | Gear Boxes |

|---|---|---|

Control COM-1000 | Item no. 02.30.80.10110 | Forward / reverse operation. |

Controll unit COM-1802 | Item no. 02.30.80.10120 | cw/ccw, infinitely variable speed control; welding torch on/off; overlap welding adjustable, controller for rotation time, 2-cycle/ 4-cycle, speed display |

Control unit COM-1803S | Item no. 02.30.80.10125 | cw/ccw rotation, infinitely variable speed control; welding torch on/off; adjustable overlap welding, controller for rotation time, 2-cycle / 4-cycle, speed display, with speed display |

Control unit COM-1803 ROB | Item no. 02.30.80.01040 | cw/ccw rotation, infinitely variable speed control; welding torch on/off; adjustable overlap welding, 2-cycle / 4-cycle, digital speed display, robot interface |

Control unit COM-1800 VSF | Item no. 02.30.80.10130 | cw/ccw rotation, infinitely variable speed control; welding torch on/off; for potentiometric foot switch |

Control unit COM-2800 | Item no. 02.30.80.10210 |

CW/ CCW rotation, infinitely variable

Speed control; welding torch

on/off; overlap welding

adjustable; pneumatic control

for automated welding

|

Control unit COM-2803S | Item no. 02.30.80.10212 | CW/ CCW rotation, infinitely variable

Speed control; welding torch

on/off; overlap welding

adjustable; pneumatic control

for automated welding, with speed display |

COM-3800 control unit for spot and tack welding

With the COM-3800, spot welds are set via the reed contact in combination with induction sensors (M6x1 screws). A spot weld (i.e. welding – > turntable stationary) or a welding bead (i.e. welding -> turntable rotating) is set at the point where the induction sensor triggers the contact. The length of the weld is controlled via the adjustable time.

The control is delivered with a table suitable for PRO2 and PRO3. The table has already 12 drilled shafts, additional shafts can be drilled on demand.

Features:

– Clockwise/anticlockwise rotation

– Stepless speed control

– Welding torch on/off

– Adjustable overlap welding

– Pneumatic control for automated welding

– Spot welding and tack welding

Data sheet